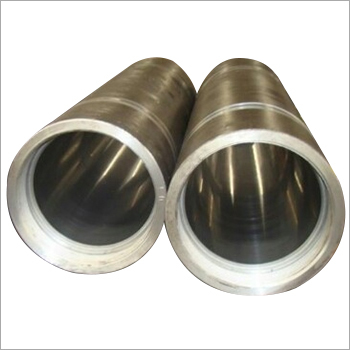

Industrial Hard Chrome Plated Roller

150 INR/Piece

Product Details:

- Diameter 50 mm to 500 mm

- Capacity Up to 20 Tons

- Material Alloy Steel / EN-8 / EN-24 / Stainless Steel

- Dimensions Customized as per requirement

- Technique Induction Hardened & Hard Chrome Plated

- Standard IS:3667

- Belt Width Up to 3000 mm

- Click to View more

X

Industrial Hard Chrome Plated Roller Price And Quantity

- 150 INR/Piece

- 1 Piece

Industrial Hard Chrome Plated Roller Product Specifications

- IS:3667

- Induction Hardened & Hard Chrome Plated

- Up to 3000 mm

- Corrosion Resistant, Highly Durable, Superior Finishing, Precision Ground

- 50 mm to 500 mm

- Alloy Steel / EN-8 / EN-24 / Stainless Steel

- Customized as per requirement

- Up to 20 Tons

Industrial Hard Chrome Plated Roller Trade Information

- 100 Piece Per Month

- 3 Days

- All India

Product Description

By utilizing skills of our dexterous workforce, we are providing a distinguished range of Industrial Hard Chrome Plated Roller. This chrome plated roll is made of supreme grade steel alloy and is coated with a thick layer of chrome to give some specific characteristics. It is suitable to be installed in lamination, rotogravure and other similar machines. The offered Industrial Hard Chrome Plated Roller is extensively demanded by our clients for its sturdiness and corrosion resistance. Moreover, we make available this chrome plated roll in different diameter and length options as per machine requirements.

High-Precision Chrome Plating for Enhanced Performance

Each roller is coated with a uniform layer of hard chrome, achieving a surface hardness of 60-65 HRC and a mirror-like finish. The plating not only provides abrasion and corrosion resistance but also improves the rollers lifespan, making it suitable for heavy-duty, continuous operation across a range of industrial sectors.

Customized Solutions Built to Your Requirements

We manufacture rollers in diameters from 50 mm to 500 mm and lengths up to 8,000 mm, along with belt widths up to 3,000 mm. Every roller is tailored to specific needs, including material selection, mounting configuration (shaft-mounted or flange-mounted), and load capacities up to 20 tons, ensuring optimal fit and compatibility for diverse industrial machinery applications.

Engineered for Reliability and Durability

Our rollers comply with IS:3667 standards and undergo induction hardening and hard chrome plating processes. This combination guarantees dependable performance, high concentricity (0.02 mm), and resistance to extreme operational conditions, including temperatures up to 200C. These features deliver consistent precision and low maintenance over years of demanding use.

FAQs of Industrial Hard Chrome Plated Roller:

Q: How do the hard chrome plating and mirror finish benefit industrial applications?

A: The hard chrome plating provides a tough, wear-resistant surface with a hardness of 60-65 HRC, significantly reducing friction and preventing abrasion. The mirror finish enhances material handling and ensures smoother operation in printing, textile, and paper mill machinery, leading to improved product quality and longer roller life.Q: What is the typical process for manufacturing these chrome plated rollers?

A: Manufacturing involves selecting suitable material (Alloy Steel, EN-8, EN-24, or Stainless Steel), followed by induction hardening for core strength. The roller is then precision ground before a 20-30 micron layer of hard chrome is electroplated, culminating in meticulous finishing to achieve tight tolerances and a mirror polish.Q: When should these rollers be used over standard rollers?

A: These chrome plated rollers should be chosen for applications demanding high load-bearing capacity, exceptional wear resistance, and operation in harsh or corrosive environments. They are ideal for heavy-duty machinery in industries like printing, paper, textiles, and any process requiring consistent precision and reliability under high stress.Q: Where can these rollers be installed in industrial plants?

A: Our hard chrome plated rollers are widely used in printing presses, textile machines, paper mills, and general industrial machinery requiring high-load handling. Their customizable sizes and mounting options (shaft or flange) make them versatile for integration into various production lines across industries.Q: What mounting options are available and how are they selected?

A: We offer both shaft-mounted and flange-mounted configurations. The choice depends on the machinery design and operational needs. Our team can recommend the optimal mounting type based on your equipment layout, ensuring secure installation and precise alignment.Q: How does the rollers concentricity of 0.02 mm impact performance?

A: High precision in concentricity ensures stable, vibration-free rotation, which is critical for applications where accuracy and uniform pressure distribution are essential. It reduces equipment wear, improves finished product quality, and extends machinery service life.Q: What advantages does the IS:3667 standard compliance provide?

A: Compliance with IS:3667 ensures the rollers meet stringent Indian standards for quality, dimensional accuracy, and performance. This guarantees reliability, safety, and consistency in both new installations and as replacement components in existing machinery.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email