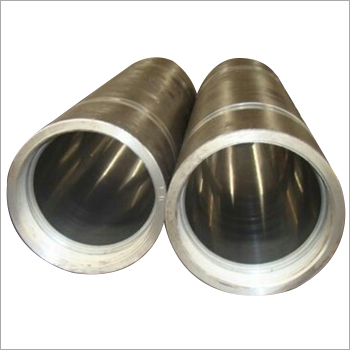

Stainless Steel Honed Tube

150.00 INR/Kilograms

Product Details:

- Mounting Type Custom/Flexible

- Efficiency High Surface Finish, Low Friction

- Temperature Range -20C to +150C Celsius (oC)

- Application Hydraulic Cylinders, Pneumatic Cylinders, Mechanical Engineering

- Connectivity Type Direct Weld/Threaded

- Accessories End Caps, Fittings Available

- Features Corrosion Resistant, Mirror Honed Finish, High Strength

- Click to View more

X

Stainless Steel Honed Tube Price And Quantity

- 150.00 INR/Kilograms

- 01 Piece

Stainless Steel Honed Tube Product Specifications

- Custom/Flexible

- 1 Year

- Circular

- Pipe

- High Surface Finish, Low Friction

- Stainless Steel

- Hydraulic Cylinders, Pneumatic Cylinders, Mechanical Engineering

- Direct Weld/Threaded

- -20C to +150C Celsius (oC)

- End Caps, Fittings Available

- Corrosion Resistant, Mirror Honed Finish, High Strength

- Precision Honed

- Up to 250 Bar Bar

- Silver

- Industrial

Stainless Steel Honed Tube Trade Information

- Cash Advance (CA), Cash in Advance (CID), Cheque

- 200 Piece Per Day

- 01 Days

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

Product Description

Stainless Steel Honed Tube

Stainless Steel Honed Tube is a highly finished tubular component which can be used as a sturdy machine element due to its high strength to weight ration and capability to withstand large machining forces and vibrations. The raw material used for the fabrication of this hollow shaft provides excellent protection against rust and corrosion which ultimately results in longer service life.Stainless Steel Honed Tube availed by us can be customized in different sizes according customer demands.

Precision Production for Industrial Needs

Our stainless steel honed tubes are manufactured using advanced processes to achieve high surface finishes and strict dimensional tolerances, ensuring compatibility with hydraulic and pneumatic cylinder applications in demanding industrial environments. Each tube is carefully inspected for surface quality and mechanical properties, offering reliable operation under pressures up to 250 Bar and temperatures ranging from -20C to +150C.

Custom Solutions and Versatile Applications

We provide customization according to drawings or specifications, enabling tailored solutions for varied mechanical engineering requirements. End types, lengths, and accessoriesincluding caps and fittingsare available to suit diverse installation and connectivity needs. Protective packaging and custom crating ensure safe delivery and installation, with options for plain and bevelled ends.

FAQs of Stainless Steel Honed Tube:

Q: How are stainless steel honed tubes manufactured to meet precise tolerances and surface finish requirements?

A: These tubes are produced using precision honing and polishing processes after seamless tube formation. The manufacturing follows ASTM A269 and EN 10305-1 standards, ensuring ISO H8/H9 tolerance and surface roughness within Ra 0.20.4 m. Each tube is thoroughly inspected to guarantee dimensional accuracy and a superior finish.Q: What applications are these honed tubes best suited for in industrial settings?

A: The honed tubes are ideal for hydraulic and pneumatic cylinders, mechanical engineering projects, and systems requiring high-efficiency, low-friction, and corrosion-resistant components. Their mirror honed finish and high-strength material make them suitable for reliable operation in high-pressure and precision environments.Q: When should custom honed tube specifications be considered for a project?

A: Custom specifications are recommended when standard dimensions or properties do not meet project requirements, such as unique lengths, diameters, wall thicknesses, or end types. Customization is available per drawing or specification to ensure optimal fit and performance for specialized applications.Q: Where can these stainless steel honed tubes be sourced in India?

A: As a distributor, manufacturer, and supplier in India, we offer direct sales and support for stainless steel honed tubes. Our reach covers major industrial regions, ensuring nationwide availability and efficient logistics for timely delivery and installation.Q: What protective measures are implemented during packaging and delivery?

A: Tubes are packaged with protective wrappings, custom crating, and careful handling to prevent surface damage and contamination during transit. Specialized packaging ensures that honed, polished surfaces maintain their integrity, ready for critical installation upon arrival.Q: How do these tubes benefit hydraulic and pneumatic systems in terms of performance?

A: Their precision honed and polished surfaces result in low friction and high sealing efficiency, reducing wear and maintenance requirements. The corrosion resistance and robust construction of stainless steel ensure long service life even in harsh operational conditions, enhancing system reliability and efficiency.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email