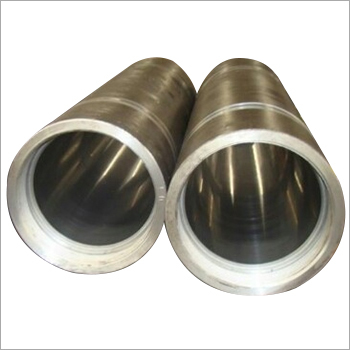

MS Seamless Honed Tubes

185 INR/Piece

Product Details:

- Accessories Matching end caps, seal kits available

- Sealing Type Standard Sealing

- Temperature Range -20C to 250C Celsius (oC)

- Mounting Type As per application

- Features Seamless finish, corrosion resistant, high strength, precision honed

- Connectivity Type Welded/Threaded

- Application Hydraulic and pneumatic cylinders, mechanical equipment

- Click to View more

X

MS Seamless Honed Tubes Price And Quantity

- 185 INR/Piece

- 01 Piece

- Cold Drawn Seamless

- Honed/Smooth (Ra 0.2 m)

- 2 mm to 25 mm

- ASTM A106/A53, DIN 2391, EN 10305

- Industrial, Hydraulic, Pneumatic applications

- Available as per requirement

- Up to 12 meters

- H8/H9 as per ISO standards

- 20 mm to 500 mm

MS Seamless Honed Tubes Product Specifications

- Standard Sealing

- -20C to 250C Celsius (oC)

- Matching end caps, seal kits available

- Welded/Threaded

- Seamless finish, corrosion resistant, high strength, precision honed

- As per application

- Circular

- Hydraulic and pneumatic cylinders, mechanical equipment

- High dimensional accuracy

- Pipe

- Up to 400 Bar Bar

- Stainless Steel

- Cold Drawn Seamless

- Honed/Smooth (Ra 0.2 m)

- 2 mm to 25 mm

- ASTM A106/A53, DIN 2391, EN 10305

- Industrial, Hydraulic, Pneumatic applications

- Available as per requirement

- Up to 12 meters

- H8/H9 as per ISO standards

- 20 mm to 500 mm

MS Seamless Honed Tubes Trade Information

- Cash Advance (CA), Cash in Advance (CID), Cheque

- 200 Piece Per Day

- 01 Days

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

Product Description

Jump on the phenomenal performance of MS Seamless Honed Tubes, crafted with astounding precision and celebrated with favorable reviews. Available in outer diameters from 20 mm to 500 mm with inner tolerances of H8/H9 as per ISO standards, these valiant tubes span up to 12 meters and feature wall thicknesses from 2 mm to 25 mm. Boasting a seamless, honed finish (Ra 0.2 m) and corrosion resistance, they serve industrial, hydraulic, and pneumatic applications effortlessly. As a top manufacturer, supplier, and distributor in India, customization and high operating efficiency are always ensured. Grab yours now and elevate your equipments reliability!

MS Seamless Honed Tubes: Proven Commercial Application

MS Seamless Honed Tubes deliver superior performance in commercial environments, especially for hydraulic and pneumatic systems. Their remarkable dimensional accuracy and seamless surface finish make them ideal for use in industrial equipment, mechanical setups, and cylinder manufacturing. Application involves direct integration into existing systems, either by welding or threading, ensuring compatibility across varied application places such as manufacturing plants, machine shops, and construction sites. These tubes excel in settings demanding durability and high pressure resilience.

Efficient Supply Rate, FOB Options & Sample Access

Our MS Seamless Honed Tubes are supplied at a competitive rate, ensuring quick and reliable handover to clients. Sale price is tailored based on customization, order volume, and timely delivery schedules. We offer convenient FOB port negotiations to match your logistics preferences. Additionally, sample availability helps customers verify product quality before committing to major orders. With robust supply capacity, we assure prompt fulfillment for both standard and custom requirements.

MS Seamless Honed Tubes: Proven Commercial Application

MS Seamless Honed Tubes deliver superior performance in commercial environments, especially for hydraulic and pneumatic systems. Their remarkable dimensional accuracy and seamless surface finish make them ideal for use in industrial equipment, mechanical setups, and cylinder manufacturing. Application involves direct integration into existing systems, either by welding or threading, ensuring compatibility across varied application places such as manufacturing plants, machine shops, and construction sites. These tubes excel in settings demanding durability and high pressure resilience.

Efficient Supply Rate, FOB Options & Sample Access

Our MS Seamless Honed Tubes are supplied at a competitive rate, ensuring quick and reliable handover to clients. Sale price is tailored based on customization, order volume, and timely delivery schedules. We offer convenient FOB port negotiations to match your logistics preferences. Additionally, sample availability helps customers verify product quality before committing to major orders. With robust supply capacity, we assure prompt fulfillment for both standard and custom requirements.

FAQs of MS Seamless Honed Tubes:

Q: How are MS Seamless Honed Tubes manufactured?

A: MS Seamless Honed Tubes are produced using a cold drawn seamless process, ensuring high dimensional accuracy and a smooth surface finish. The tubes are then honed to achieve an Ra 0.2 m, creating precision for hydraulic and pneumatic applications.Q: What standards do these tubes comply with?

A: These tubes are manufactured in adherence to global standards such as ASTM A106/A53, DIN 2391, and EN 10305, ensuring reliability, safety, and performance consistency across industries.Q: When should I use MS Seamless Honed Tubes?

A: Use these honed tubes when your application requires high strength, corrosion resistance, and exceptional dimensional precision, particularly in hydraulic or pneumatic cylinders and mechanical equipment.Q: Where can MS Seamless Honed Tubes be installed?

A: These tubes are suitable for installation in industrial environments, hydraulic press plants, pneumatic systems, and mechanical structures, providing efficient and reliable operation even under high pressure and temperature.Q: What are the primary benefits of using these tubes?

A: The main benefits are seamless finish, excellent corrosion resistance, high strength, and precise dimensions, which result in improved equipment efficiency and longer service life.Q: How can I customize MS Seamless Honed Tubes to meet my requirements?

A: Customization options include varying the diameter, wall thickness, lengths, and connectivity type (welded or threaded). Accessories like matching end caps and seal kits are also available upon request.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email