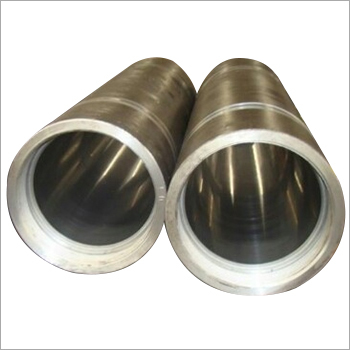

Telescopic Hydraulic Cylinder

25000 INR/Piece

Product Details:

- Connectivity Type Hydraulic Connections

- Sealing Type Polyurethane / Nitrile Seals

- Features Multi-stage Extension, Leak-Proof, Robust Construction

- Flow Rate Customizable

- Application Tippers, Dump Trucks, Industrial Lifting Equipment, Construction Machinery

- Mounting Type Trunnion / Clevis / Flange Mounted

- Temperature Range -20C to +80C Celsius (oC)

- Click to View more

X

Telescopic Hydraulic Cylinder Price And Quantity

- 25000 INR/Piece

- 01 Piece

- Yes

- High Strength Alloy Steel

- Polished / Painted

- As per Dimensions

- Up to 6000 mm

- 40 mm to 300 mm

- Hard Chrome Plated Rod

- 2 to 6 Stages

Telescopic Hydraulic Cylinder Product Specifications

- Polyurethane / Nitrile Seals

- Hydraulic Connections

- Multi-stage Extension, Leak-Proof, Robust Construction

- Tippers, Dump Trucks, Industrial Lifting Equipment, Construction Machinery

- Customizable

- Circular

- Trunnion / Clevis / Flange Mounted

- -20C to +80C Celsius (oC)

- Pipe

- High Force Output

- High Efficiency

- Fittings, Mounting Brackets

- Up to 250 bar Bar

- Stainless Steel

- Yes

- High Strength Alloy Steel

- Polished / Painted

- As per Dimensions

- Up to 6000 mm

- 40 mm to 300 mm

- Hard Chrome Plated Rod

- 2 to 6 Stages

Telescopic Hydraulic Cylinder Trade Information

- 200 Piece Per Day

- 01 Days

Product Description

Telescopic Hydraulic Cylinder is a heavy-duty fluid power transmitting element that is specially designed for hydraulically powered industrial machines to deliver power in a controlled manner. It is made up of low allow steel with a grade value of ST52 that offers good impact resistance. The ends are provided with eye-connectors to easily install this machine spare with high rigidity. The offered Telescopic Hydraulic Cylinder comes in various sizes with a maximum stroke of 500 millimeters.

Specification

|

Material |

ST52 |

|

Structure Type |

Round |

|

Rod Diameter |

50 mm |

|

Maximum Stroke |

100-500 mm |

|

Working Pressure |

50-200 Kg |

Engineered for Heavy-Duty Performance

This telescopic hydraulic cylinder features up to 6 extension stages and delivers high force output, making it a top choice for demanding applications such as dump trucks and construction machinery. Its robust structure and excellent efficiency ensure reliable operation in rigorous environments.

Superior Materials and Surface Protection

Constructed with a stainless steel body and a high-strength alloy steel piston rod, the cylinder undergoes hard chrome plating and precision finishing for optimum corrosion resistance. Choose between polished or painted finishes based on environmental needs, ensuring lasting durability.

Flexible Installation and Customization

The cylinder accommodates various mounting requirements, including trunnion, clevis, and flange types, allowing for seamless integration across different machinery. Additionally, customizable stroke lengths, flow rates, and sealing types make it adaptable to a wide range of operational needs.

FAQs of Telescopic Hydraulic Cylinder:

Q: How do I select the appropriate telescopic hydraulic cylinder configuration for my equipment?

A: To choose the right configuration, consider your required stroke length (up to 6000 mm), bore diameter (40 mm to 300 mm), and the number of stages (2 to 6). Evaluate your machinerys force and speed needs, mounting style (trunnion, clevis, or flange), and environmental conditions for surface finish and seal compatibility.Q: What process is involved in installing these cylinders in industrial machinery?

A: Installation begins by matching the cylinders mounting type (trunnion, clevis, or flange) with your equipment. Attach the supplied brackets and fittings, connect the hydraulic lines, and ensure all seals and mounting points are securely fastened. Test for leaks prior to full operation.Q: When should telescopic hydraulic cylinders be used over standard hydraulic cylinders?

A: Telescopic cylinders are ideal when a long extension with compact retraction is necessary, such as in dump trucks or lifting equipment. Their multi-stage design delivers greater stroke lengths without excessive overall retracted length, making them suitable for applications requiring both compactness and reach.Q: Where can I source these hydraulic cylinders in India?

A: These telescopic hydraulic cylinders can be sourced directly from established distributors, manufacturers, and suppliers throughout India. You can contact vendors specializing in hydraulic solutions for construction machinery, industrial vehicles, and heavy equipment.Q: What are the main benefits of a hard chrome-plated rod and stainless steel body?

A: A hard chrome-plated rod provides enhanced wear and corrosion resistance, reducing maintenance needs and extending the cylinders service life. The stainless steel body protects against rust and environmental damage, ensuring robust, reliable operation in harsh conditions.Q: How does the adjustable speed feature benefit operational efficiency?

A: Adjustable speed allows operators to control the extension and retraction rates based on the specific application, enhancing precision and safety. This flexibility contributes to greater overall efficiency, especially in dynamic and varied working environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email